Our Distillery

Fullarton Distilleries is a family run facility based in Candepar, Goa, India.

Where Great Spirits Begin: Inside Our Distillery

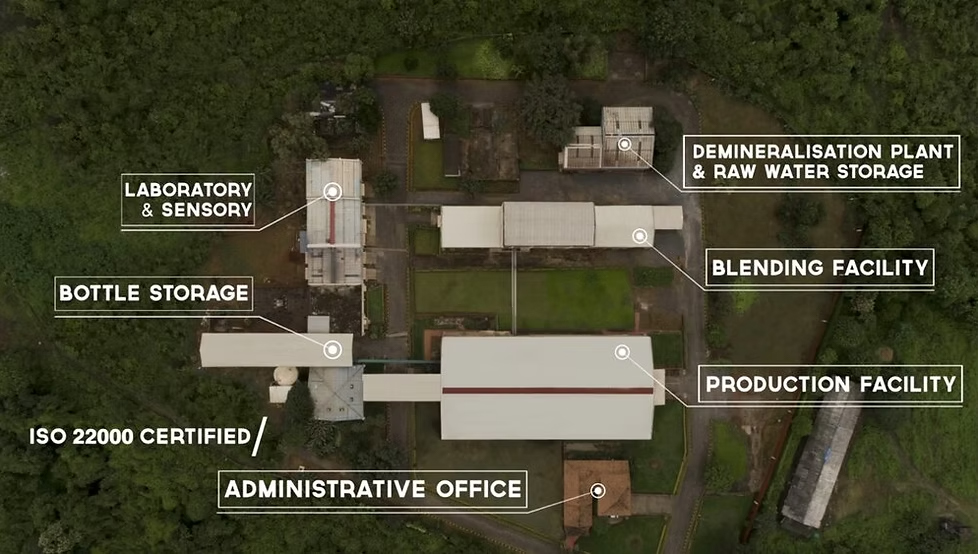

Nestled in the lush heart of Goa, the Fullarton Distillery is where expertise meets precision—crafted to deliver premium, globally benchmarked spirits.

Built across 11 acres, the facility is designed to meet international standards in both equipment and personnel. With a strong focus on process integrity and craft precision, it offers the flexibility to handle high-volume production as well as small-batch customization.

Strategically located near Mormugao Port, the distillery is also optimized for global trade—supporting efficient export logistics and seamless supply chain operations. From infrastructure to innovation, Fullarton is built for the world.

A Deep Dive into Our Facility

Water Treatment: The First Ingredient

Our distillation journey begins with water.

A 400,000L underground raw water tank is fed by the municipal supply.

Water is processed through a 5,000 L/hr demineralisation plant (with a 2,000 L/hr backup).

Demineralised (DM) water is stored in 40,000L tanks, ensuring purity and consistency in every blend.

Blending Facility: Craft, Scaled

Precision blending is our signature.

280,000L of ENA storage (via 4x50KL + 4x20KL tanks)

Dedicated tanks for specialty spirits like malt—ranging from 1KL to 27KL

14 dedicated blending tanks: ideal for small and large batch production

Additional infrastructure includes a caramel mixer, sugar syrup maker, and our in-house vapour infusion tank, built for temperature precision using electric indirect heating—unlike typical steam-based systems.

Production Lines: Designed for Versatility

Our four bottling lines allow high output with product-specific detailing:

Line 1 – High-Speed PET Bottling

Dedicated to 50ml PET bottles

Fully automated; up to 240 bottles/min

Features include unscrambler, monoblock filler-sealer, dual QC inspection, linear labeller, and batch coder.

Line 2 – Versatile Glass Line

Formats: 50ml, 90ml, and 750ml

Output: 160bpm / 120bpm / 60bpm respectively

Enhanced with bottle washers and format-specific tech.

Line 3 – Flexible Semi-Auto Line

Supports 90ml to 1L formats, across all shapes and materials

Includes both manual and automatic capping options (ROPP, Guala, cork)

Integrated QC, shrink tunnel, and packaging flow.

Line 4 – Sachet Line

6x FFS (Form-Fill-Seal) machines

120 pouches/min for 50ml sachets

Compact and ideal for high-volume SKUs.

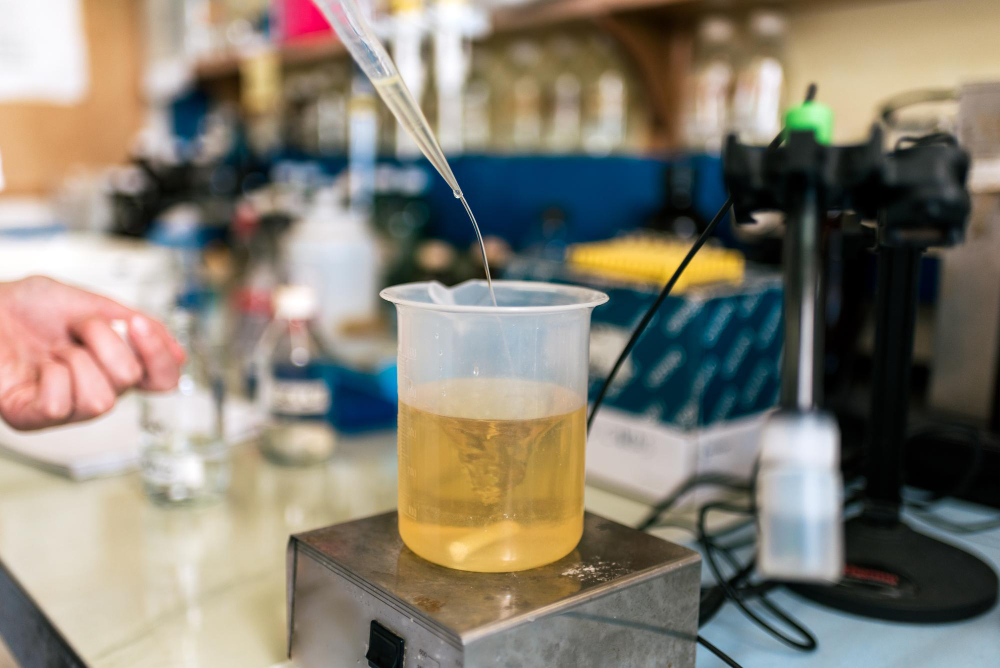

Laboratory & Sensory Suite

Our on-site Quality Lab & Sensory Facility ensures each product meets global standards.

Lab Features:

Conductivity meter, pH meter, nephelometer, TDS analyzer

Colorimeter, hydrometer, and packing material instrumentation

R&D-focused to enable formulation and packaging experiments.

Sensory Room:

A calibrated environment for tasting, consistency, and product development.

Maturation, Storage & Experience

At Fullarton, aging, logistics, and storytelling come together under one roof.

Our cask program spans more than 400 barrels, stored across multiple climate-optimized cellars designed for both long-term maturation and experimental blends. This aging infrastructure allows us to craft spirits with depth, character, and consistency.

Our fully integrated storage ecosystem includes:

Dedicated godowns for raw materials and finished goods

Bottle storage with direct conveyor access to the production line

Packaging material storage across more than 850 square meters

Anchoring this ecosystem is our Experience Centre—a modular bar and lounge space designed for tastings, intimate press gatherings, and curated private events. It reflects our ongoing commitment to quality, hospitality, and the evolving narrative of craft spirits.

Let's Talk

Looking for a world-class manufacturing and bottling partner in India?

At Fullarton, we have the expertise, infrastructure, and craftsmanship to bring your spirit to life.

Let’s connect and build something extraordinary.